بالعربية

Français

русский язык

Português

ภาษาไทย

Türkçe

Español

فارسی

היברית

ViệtName

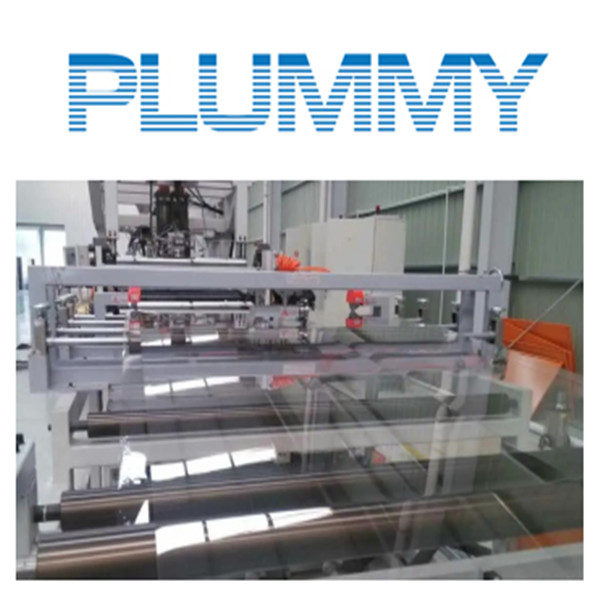

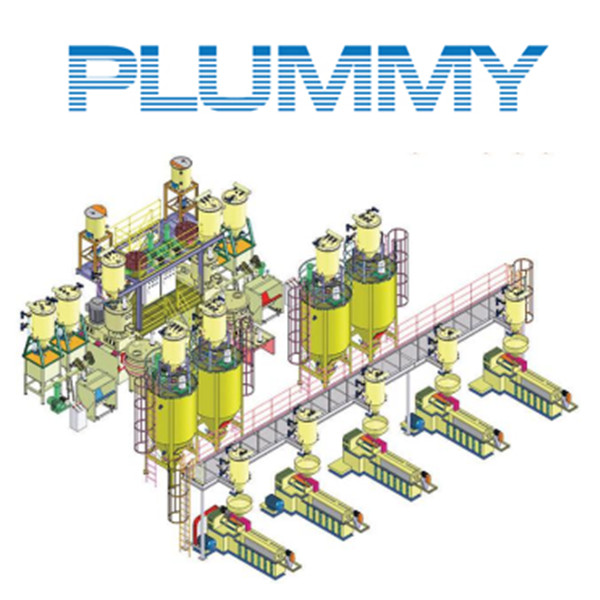

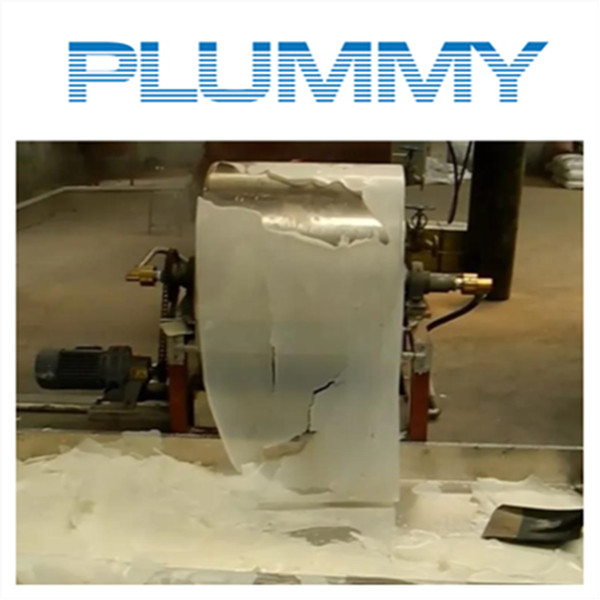

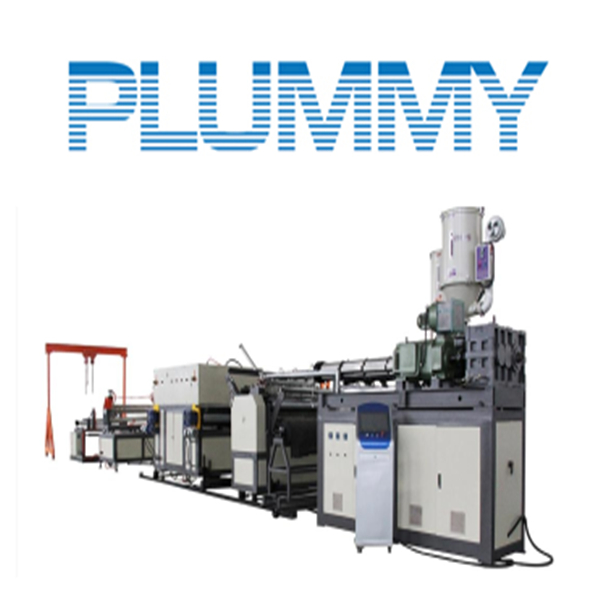

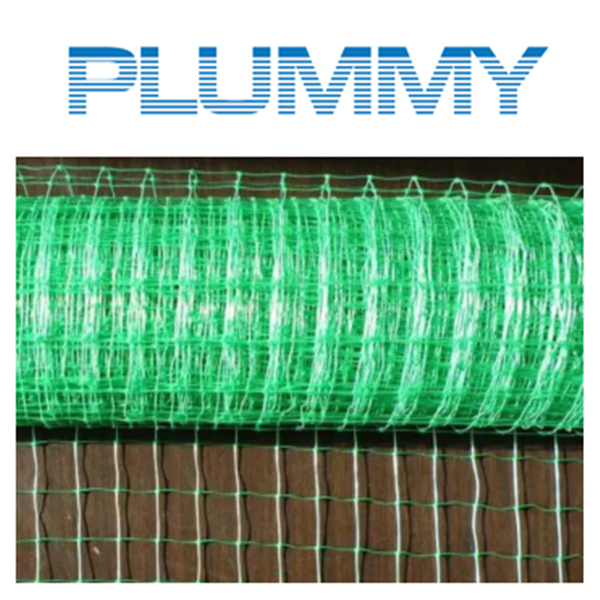

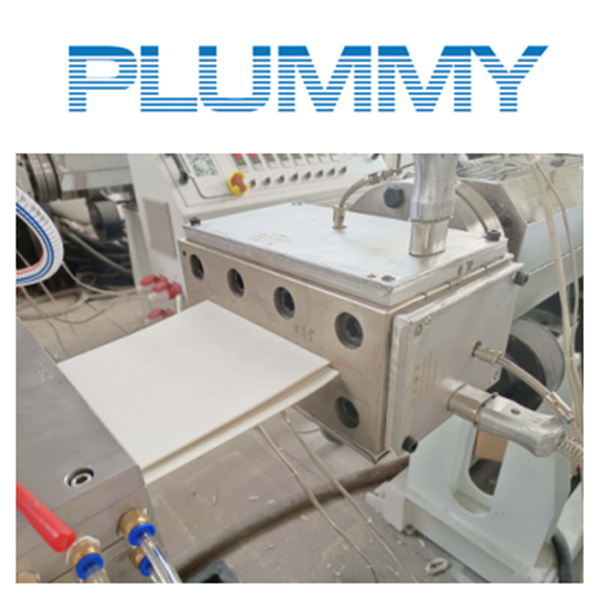

Zhangjiagang Plummytech Imp&Exp Co.,Ltd is a key enterprise of national professional manufacturer of plastic machinery. The company is located in the economy developed golden delta of lower reaches of the Yangtse River. Which is the National civilized and sanitation city. It is with Shanghai in the east, it extends as far as Nanjing in the west and extends as far as Suzhou, Wuxi and Changzhou in the south. The city faces the river and extends the sea. The land and water transport is very convenient.Thanks to our advanced Research & Development and experienced technicians, Plummytech Im···